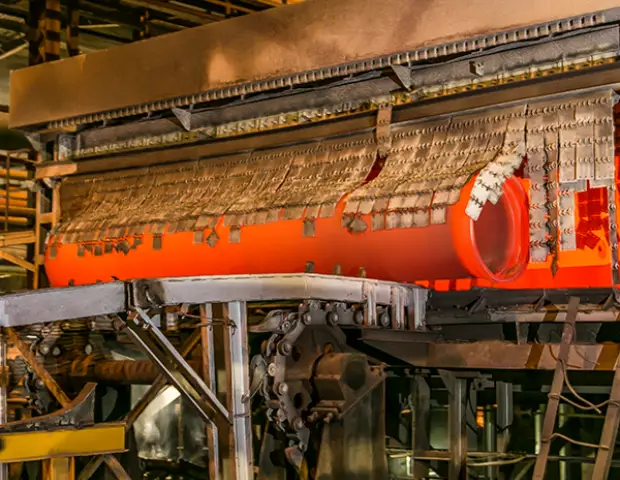

DI Pipes

Advantages of Ductile Iron Pipe

-

Tremendous Tensile Strength

Tremendous Tensile Strength

-

Pressure bearing ability

Pressure bearing ability

-

Withstands Severe Crushing Loads

Withstands Severe Crushing Loads

-

Great beam Strength

Great beam Strength

-

Corrosion resistant

Corrosion resistant

-

High Impact Resistance

High Impact Resistance

-

High Bursting Strength

High Bursting Strength

-

Sustains external static/dynamic loading

Sustains external static/dynamic loading

-

Easy to Install

Easy to Install

-

Minimal installation cost

Minimal installation cost

-

Zero Maintenance

Zero Maintenance

-

No Cathodic Protection

No Cathodic Protection

-

Low pumping cost

Low pumping cost

-

Excellent hydraulic features

Excellent hydraulic features

Rashmi Metaliks: Global Leader in Ductile Iron Pipe Solutions

Product Range

Our DI Pipes offer:

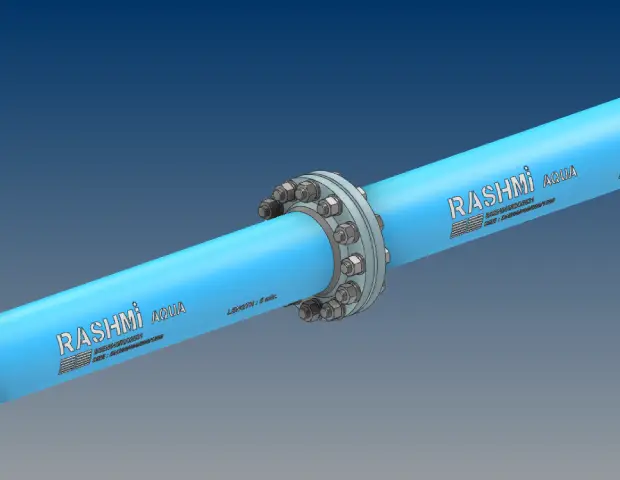

| Product | Ductile Iron (DI) Pipes suitable for Push-on-Joints* |

| Size Range | DN 80 to DN 1200 |

| Class of DI Pipes | C20, C25, C30, C40, C50, C64, C100, PP, K-7 & K-9 |

| Standard Length (in Meters) | 5.5 |

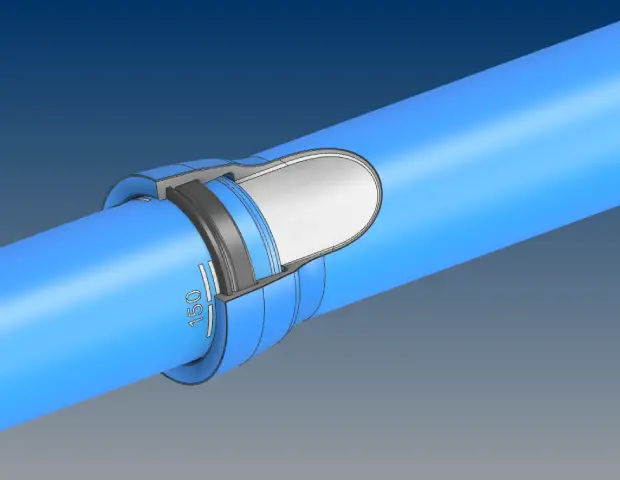

| Types | Push-on Joint, Restrained Joint |

| Internal Linings |

|

| External Coating - 1 |

|

| External Coating - 2 |

|

| Conforming Specifications | IS 8329/IS 9523, ISO 2531/BS EN 545, ISO 2531, ISO 7186, BS EN 598, ISO 4179 & ISO 8179 |

Mechanical Properties of DI Pipes by Rashmi Metaliks Limited |

|

|---|---|

| Mechanical Properties | Ductile Iron (DI) Pipes suitable for Push-on-Joints* |

| Minimum Ultimate Tensile Strength | Min. 420 MPA |

| Proof Strength | Min. 270 MPA |

| Minimum Elongation | DN40 to DN1000- 10%, DN1100 to DN2000-7% |

| Modulus of Elasticity | DN40 to DN1000- 10%, DN1100 to DN2000-7% |

| Hardness | Max. 230 HBW |

| Density | 7,050 Kg per cubic meter |

| Coefficient of Thermal Expansion | 11.5 x 10-6 per degree celsius (°C) (for temperature range 200°C -1000°C) |

| Impact Strength | At Normal Temperature - 7 ft-lb (minimium) & At Low temperature - 3 ft-lb (minimum) |

Angular Deflection of DI Pipes by Rashmi Metaliks Limited |

|

|---|---|

| Diameter Range (DN) | Angular Deflection |

| DN 80 - DN 150 | 4° |

| DN 200 - DN 300 | 4° |

| DN 350-DN 600 | 3° |

| DN 700 - DN 800 | 2° |

| DN 900 - DN 1000 | - |

| DN 1100 - DN 1200 | - |